In this instruction, Obd2tool.com show you guide on how to change hydraulic system oil for Caterpillar 950F excavator. More repair case for CAT machine,please refer to:Caterpillar Trouble Repair.Caterpillar Trouble Repair.

Procedures:

NOTICE

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing,adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.

Dispose of all fluids according to local regulations and mandates.

1.Operate the machine in order to warm the hydraulic oil.

2.Park the machine on level ground. Lower the attachment to the ground and apply slight downward pressure. Engage the parking brake and stop the engine.

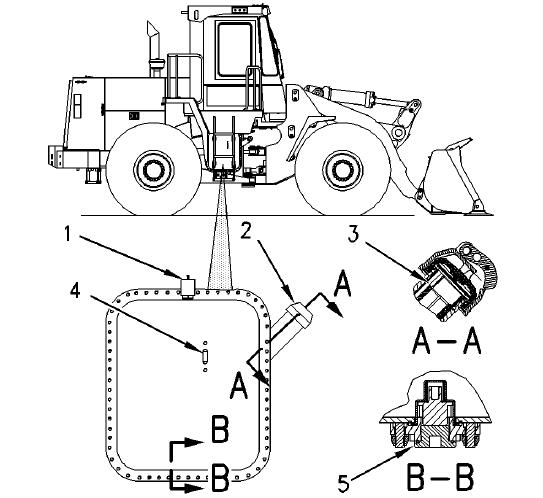

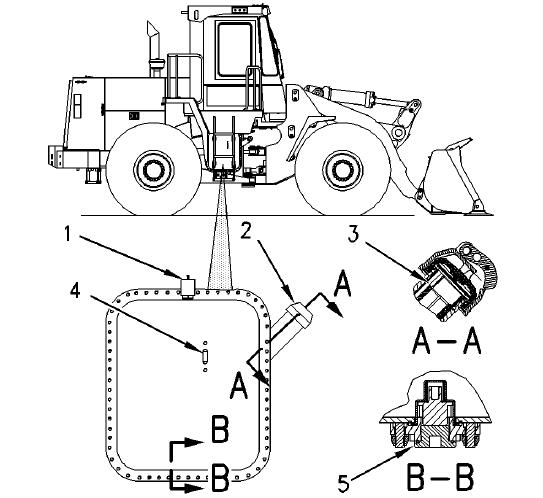

3.The hydraulic tank is located on the right side of the machine. Press the button on the breaker relief valve (1) in order to relieve any tank pressure.

4.Remove the hydraulic tank filler cap (2) and the filler strainer (3). Wash the filler cap and the strainer in a clean, nonflammable solvent. Install the strainer.

5.Inspect the gasket on the hydraulic tank filler cap for damage. Replace the gasket, if necessary.

6.Remove the drain plug (5) from the bottom of the hydraulic tank. Wash the drain plug in a clean, nonflammable solvent.

7.The hydraulic tank is equipped with an ecology drain valve. Attach a hose to a 126-7914 Oil Drain Coupling. Install the threaded end of the coupling into the drain valve in order to unseat the internal drain valve.

NOTICE

Never start the engine while the hydraulic oil tank is being drained or while the hydraulic oil tank is empty.

Excessive wear and damage to the hydraulic components can occur.

8.Close the drain valve. Install the drain plug.

9.Change the hydraulic oil filter.

10.Fill the hydraulic tank with clean oil. Make sure that the oil level is at the “FULL” mark on the sight gauge (4). Install the filler cap.

11.Start the engine and run the engine for at least ten seconds. Then, stop the engine and add hydraulic oil to the tank until the oil level is at the “FULL” mark on the sight gauge. Install the

filler cap.

12.Start the engine and run the engine at low idle. Cycle the implements so that all hydraulic systems are filled with oil.

Note: If the alert indicator for a low oil level comes on, stop the engine and immediately add oil to the hydraulic tank. The oil level should not be below the suction ports in the hydraulic tank while the engine is running.

13.Add hydraulic oil to the tank until the oil level is at the “FULL” mark on the sight gauge.

14.Stop the engine. Top off the hydraulic tank so that the oil level is at the “FULL” mark on the sight gauge. Install the filler cap.

Note: The oil must be free of air bubbles. If air bubbles are present in the hydraulic oil, air is entering the hydraulic system. Inspect the hydraulic suction line and the hose clamps.

15.If necessary, tighten any loose clamps or any loose connections. Replace any damaged hoses.