Category: Auto Scanner Tools

Auto Scanner Tools are hot sale

How to Pay and Get the Autel Update Service

Why You Need Autel Software Subscription (TCP) ? Stay current with the latest Autel software versions and increase the value of your investment with the…

Mercedes-Benz How to Reset a Check Engine Light

Whether you drive a Mercedes-Benz or a model from another make, you can reset the check engine light by using an appropriate scanner or by…

Jdiag P200 Smart Hook Use Tutorials

Jdiag P200 Smart hook is the newest generation intelligence circuit tester with 2.4 inch large size LCD screen display, it is dedicated to test all…

Fixed! Ford VCM2 Clone IDS Unable to Connect to Ford Mondeo

Problem: I bought a VCM2 IDS, it works with ids 101.01 in VMware 10 with XP SP3. But, although it connects well to ids and…

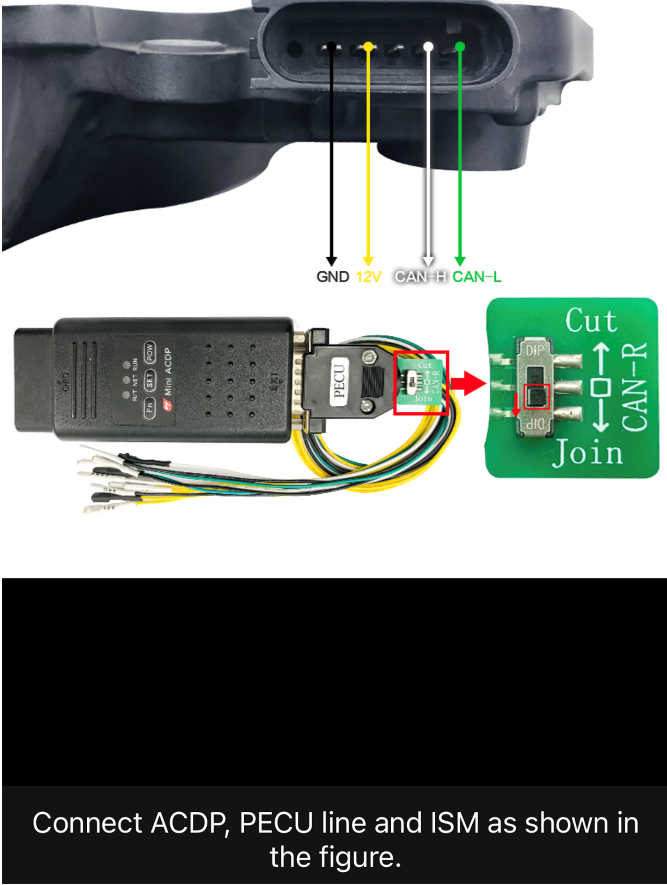

Yanhua Mini ACDP Module 18 Mercedes-Benz DMEISM Refresh Operation Guide

Update: Yanhua Mini ACDP Module 18 Mercedes-Benz DME/ISM refresh, no soldering, no risk. Module 18 function: 1. Support Mercedes Benz DME refresh for: CR3.XX/CR4.XX/CR5/CR6/CR60.XX/SIM271DE2.0/SIM4LKE/SIM271KE2.0/CRD.11/CRD2.XX/ME9.7/MED17.7.X/SIM266 etc. 2….

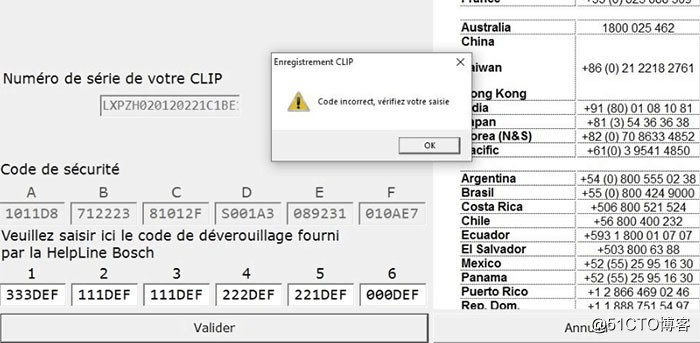

How to solve the problem of incorrect Renault Can Clip code?

Recently, many customers stated that they failed to activate the Renault Can Clip software. As shown below, an error message “Code incorrect, verifiez votre saisie…

Program 09 Malibu Keyfob with GM TECH2, Autel MP808, MK808 etc

Have 09 Chevy Malibu, we lost one remote and I would like to add one. How to do it? Go to the dealer? Also, you…

How To Activate “Flight Recorder” For Micropod 2 & VCI Pod

Look here: built a trigger and activate “Flight Recorder” for Micropod 2 & VCI Pod I know the micropod 2 and Witech has a “Flight Recorder”…

How to Check Real Mileage by Delphi DS150 on Renault Megane Scenic 3

This article is show you guide on how to use Delphi Ds 150 to check real kilometers for Renault Megane Scenic3. .More repair cases for…

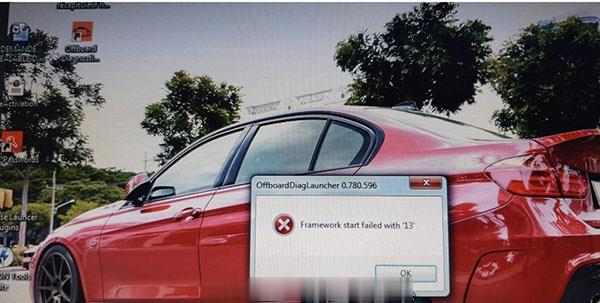

How to Solve ODIS V5.1.6 Software Framework start failed with “13” Error

Customer problem: When I install ODIS V5.1.6 software by my VAS6154 diagnostic interface. An error pops up with the words “Framework start failed with “13”…